An anniversary that went unnoticed: This year, Renault is celebrating the 55th anniversary of its composite material ‘bumper’. Although it first appeared as a single piece in 1972 on the R5, it was initially used as a belt around the rear bumper of the R17. However, as early as 1968, it was present on the models of the 120 project for a large saloon (below), which was slowly transformed into the Renault 30. Paradoxically, the latter was never fitted with this famous bumper!

So it was the Renault 5 (project 122) that first received this protection and safety feature. But in fact, what would this model have looked like if it hadn’t been fitted with this element? Well, like this model of the R5 below, where there was no mention of these “shields” for this project…

Fortunately, Yves Georges, head of the design department, and Claude Prost-Dame, then head of bodywork, imposed this solution on the 122 project. Gaston Juchet, the head of styling, took charge of integrating it into the galet styling of the little Renault. It wasn’t easy to sell the idea that a plastic element was more expensive than a bumper covered in chrome!

The advantage of the shield, in addition to its ability to absorb impacts at speeds of up to 7 km/h, is that it provides a higher level of protection than a sheet metal bumper. To ensure that this new element fulfils its function, the material chosen consists of glass fibres impregnated with polyester resin. This is an innovation that has led Renault to take a technical gamble requiring major investment.

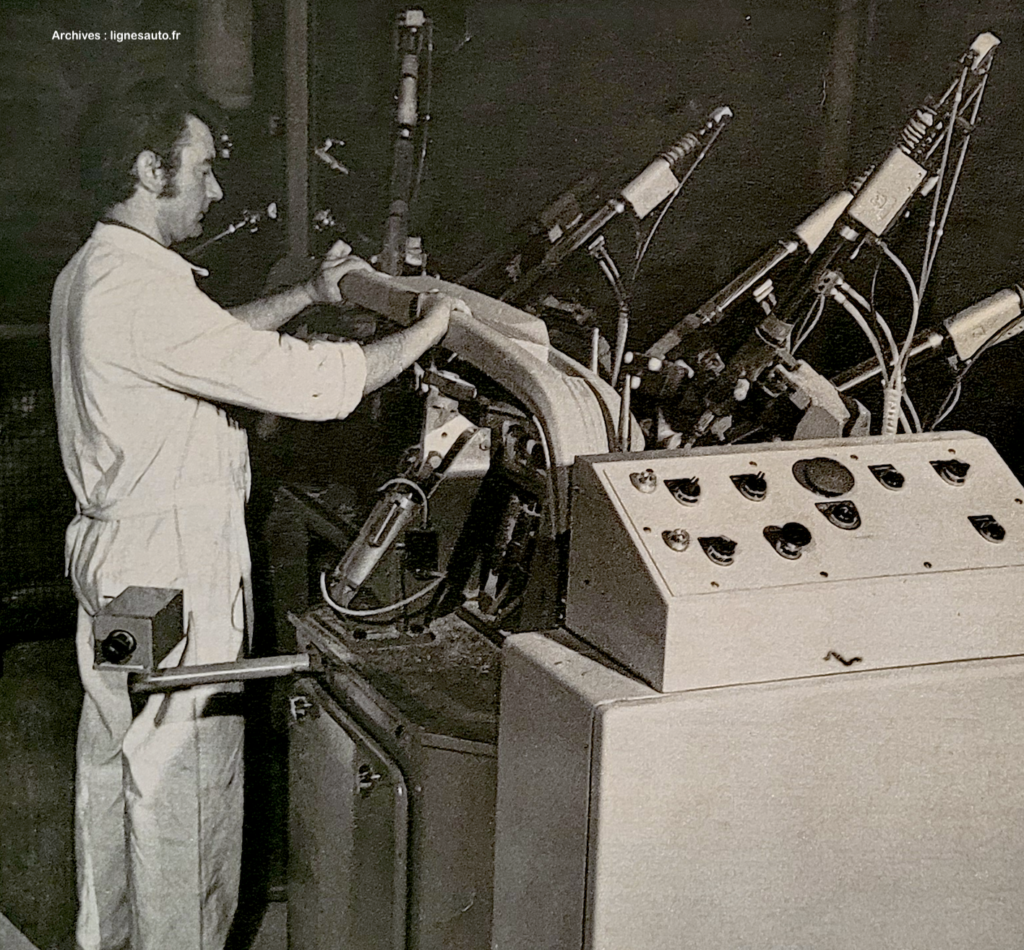

The product obtained from the fibreglass and polyester resin is then treated to produce a material with the consistency of a thick mastic. It is then wound onto 1.5 tonne reels and delivered to the Dreux plant, which is specially equipped to produce these bumpers.

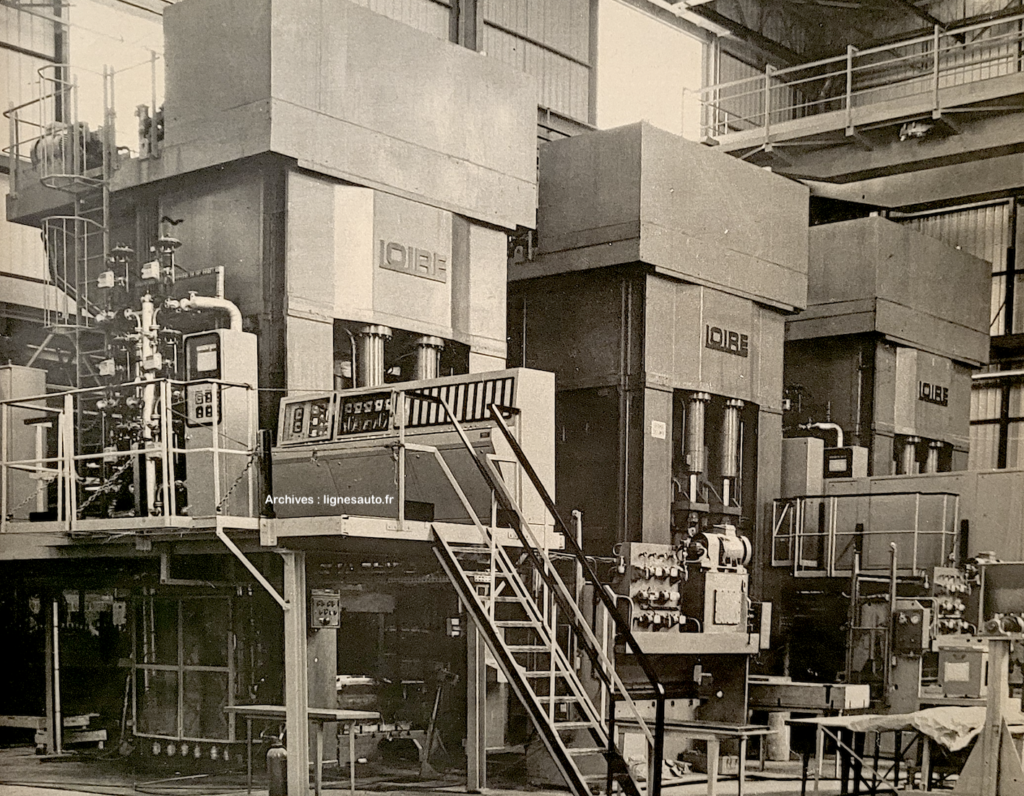

Presses weighing 1,500 tonnes (above) shape them at a temperature of 150° to enable thermosetting, all at a pressing force of around 70 kg per cm2. Each press can produce forty pieces an hour, of which there are four. This innovative material was perfectly suited to the 1970s, when synthetics were widely used in areas as diverse as furniture, clothing and household accessories.

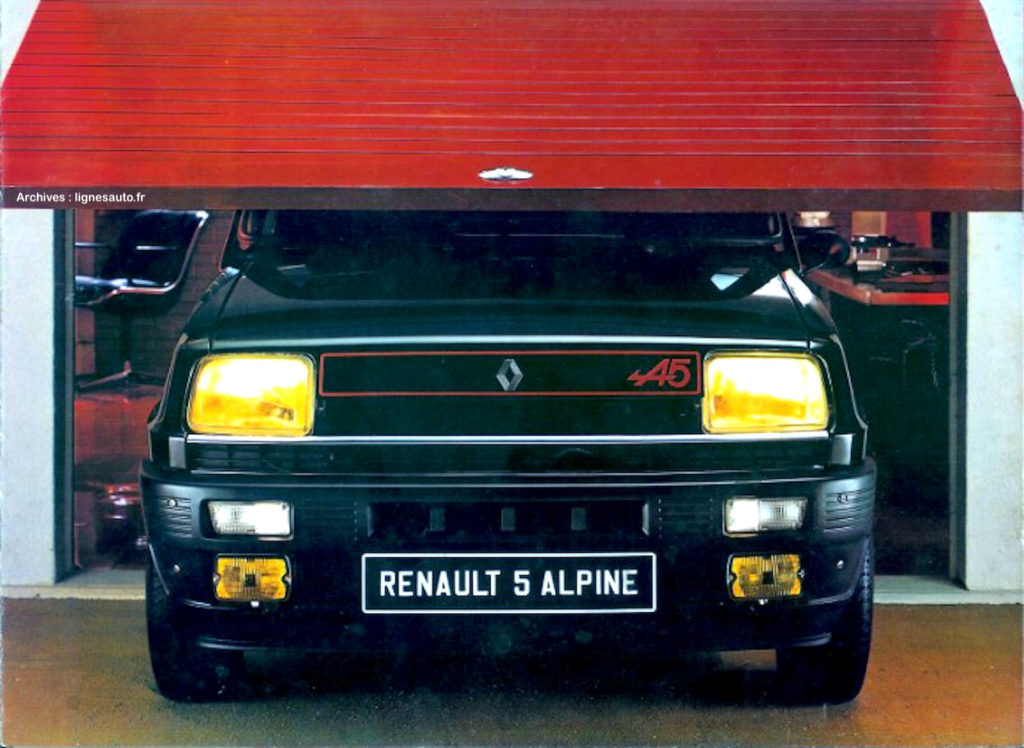

The result is fantastic, with these light grey parts playing a full part in the R5’s styling. However, these composite components go well beyond the purely stylistic or protective aspects. They offer the possibility of reducing the number of parts making up the structure, by eliminating a few sheet metal elements in the lower front section of the vehicle.

Renault therefore decided to favour this solution for its future projects, even if it meant going overboard, as in this study of a city car from the VBG programme in 1977, designed by Marc Deschamps (above). The bumpers had already been fitted to the sides of the R5 GTL in 1976, but on this model, they leave little room for sheet metal! And what can we say about this other VBG model below, which is similarly fitted with these protective bumpers?

In 1976, bumpers were a natural part of the styling of the R14 (below) designed by Robert Broyer, but unlike on the R5, their integration here was more delicate because the wings of the compact saloon were more developed and, in the end, they were less well protected than expected. The R30 (1975) and R18 (1978) retained the curved blade bumpers.

Clean, simple and straightforward, the shield solution has since become widespread. From a protective shield, it has become soft-nose, with many more innovations that have a direct impact on the design of current and future cars…